What are the practical applications of flame retardant fabrics?

2025-07-14

Flame retardant fabrics have become core materials in the fields of industrial safety and public protection due to their characteristics of "difficult to burn when exposed to fire and self-extinguishing when away from fire". Their application scenarios are constantly expanding with the upgrading of technology, and they have built a comprehensive safety line from passive fire protection to active protection.

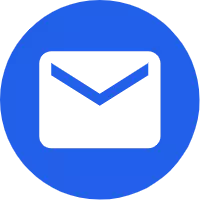

In industrial scenarios, flame retardant fabrics are "life-saving clothes" for high-risk positions. In petrochemical, welding and cutting working environments, the flame-retardant work clothes worn by workers are made of aramid and cotton blended fabrics with a limiting oxygen index (LOI) of more than 28% (ordinary fabrics are only 18-20%), which can withstand 5-10 seconds in the flame without melting, buying time for escape. High-temperature resistant flame retardant fabrics in the metallurgical industry can withstand instantaneous high temperatures of 200-300℃ and effectively block spark burns.

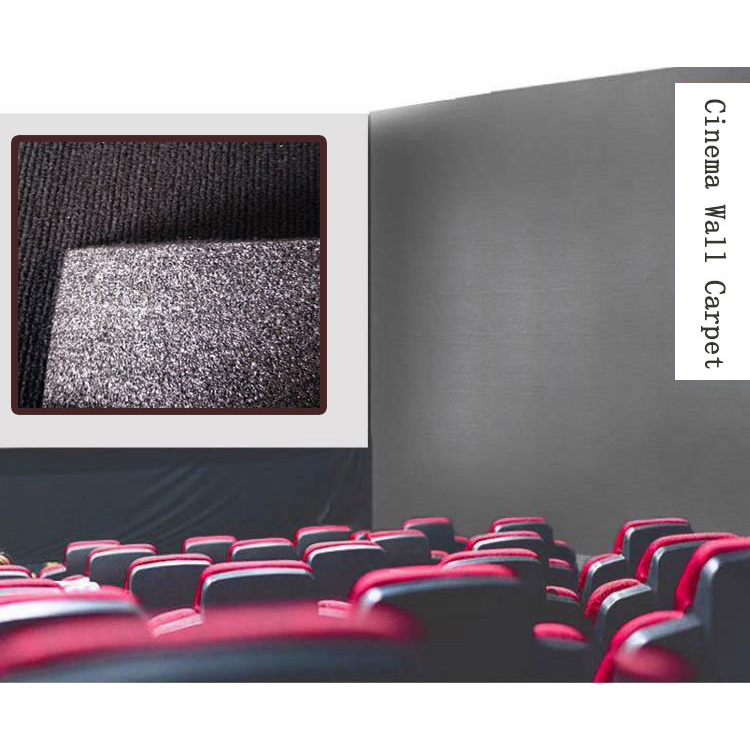

Public gathering places rely on flame retardant fabrics to reduce fire risks. Theater seats and hotel curtains are mostly made of flame-retardant polyester fiber fabrics. After post-finishing, the burning speed is ≤100mm/min, and there is no molten dripping. Carpets in KTVs, shopping malls and other places are made of flame-retardant nylon. When exposed to fire, they carbonize to form an insulation layer, delaying the spread of fire and buying the critical 10 minutes for personnel evacuation.

The application of flame retardant fabrics in the home field is becoming more and more popular. Mattresses and sofa fabrics meet the GB 17927.1 flame retardant standard by adding phosphorus flame retardants, and they will extinguish themselves within 30 seconds of contact with open flames. Children's bedding uses flame retardant cotton fabrics, which are both soft and safe to prevent children from playing and contacting open flames. Flame-retardant silicone coated fabrics are used in kitchen aprons and heat-insulating gloves, which are resistant to temperatures of 250℃ to prevent hot oil splashes.

The transportation field has strict requirements for flame retardant fabrics. Aircraft seat covers are made of aramid flame retardant fabrics, which meet FAR 25.853 standards, with a burning afterflame time of ≤15 seconds and a smoke toxicity level of FV-0. The curtains and seat fabrics of the high-speed rail interior have passed the GB 50222 flame retardant test, and the combustion performance has reached B1 level. Even if there is a fire in the car, the flame spread can be suppressed. Car mats and seat fabrics are mostly flame retardant polyurethane composite materials, with a shrinkage rate of less than 5% when exposed to fire, reducing the toxic gases produced by combustion.

Special protection scenarios highlight technical advantages. The outer layer of the fire suit uses flame-retardant Nomex fabric, which can maintain integrity in 800℃ flames; forest fire suits are added with aluminum hydroxide flame retardant, which has both waterproof and flame retardant properties. The flame retardant camouflage fabrics used in tents and camouflage nets in the military field can be concealed and fireproof in the wild environment, adapting to complex combat needs.

From daily homes to high-risk industries, flame retardant fabrics minimize fire hazards through the triple protection of "preventing combustion, delaying spread, and reducing toxicity." Its application is not only a rigid requirement of safety standards, but also a key means to curb fire accidents from the source. With the advancement of material technology, flame retardant fabrics are developing in the direction of being lighter, more comfortable and multifunctional, providing more reliable material support for safety protection in various fields.