What Makes Fiberglass Ceiling a Smarter Choice for Modern Buildings?

2025-11-14

Fiberglass ceiling has become a widely adopted interior solution across commercial complexes, educational institutions, healthcare facilities, and high-end residential spaces. Known for its lightweight structure, excellent acoustic absorption, fire resistance, and design versatility, this material plays a crucial role in shaping comfortable and energy-efficient interiors.

What Defines a Fiberglass Ceiling and Why Does It Matter in Modern Applications?

Fiberglass ceiling refers to a panel or tile made from fine glass fibers bonded with a strengthening binder. The material is engineered to deliver superior acoustic control, thermal stability, and safety performance. As modern buildings increasingly emphasize comfort, energy efficiency, and environmental protection, fiberglass ceiling has gained strong visibility in the global construction market.

A well-designed fiberglass ceiling not only improves the interior environment but also contributes to energy savings and long-term durability. This section examines what the product truly offers and why architects, engineers, and contractors choose it over alternative ceiling materials.

Key Product Parameters

To demonstrate technical professionalism, the following table summarizes typical fiberglass ceiling specifications:

| Parameter | Specification Range |

|---|---|

| Material Composition | High-density fiberglass core |

| Surface Finish | Painted fiberglass veil / acoustic fleece |

| Density | 80–120 kg/m³ |

| Thickness | 15 mm, 20 mm, 25 mm (customizable) |

| NRC (Noise Reduction Coefficient) | 0.80 – 1.00 |

| Fire Rating | Class A / Class 1 according to various standards |

| Thermal Conductivity | 0.031–0.040 W/m·K |

| Moisture Resistance | High performance, dimensionally stable |

| Standard Size | 600×600 mm, 600×1200 mm, custom sizes available |

| Installation System | T-grid suspension, concealed frame systems |

These parameters illustrate how fiberglass ceiling panels perform across acoustic, thermal, structural, and safety dimensions.

Why Is the Material Structure Important?

Fiberglass has a porous internal network that traps sound waves rather than reflecting them. This structural advantage allows the ceiling to deliver an outstanding NRC rating, improving speech clarity and reducing background noise in busy interiors such as offices, schools, airports, and call centers.

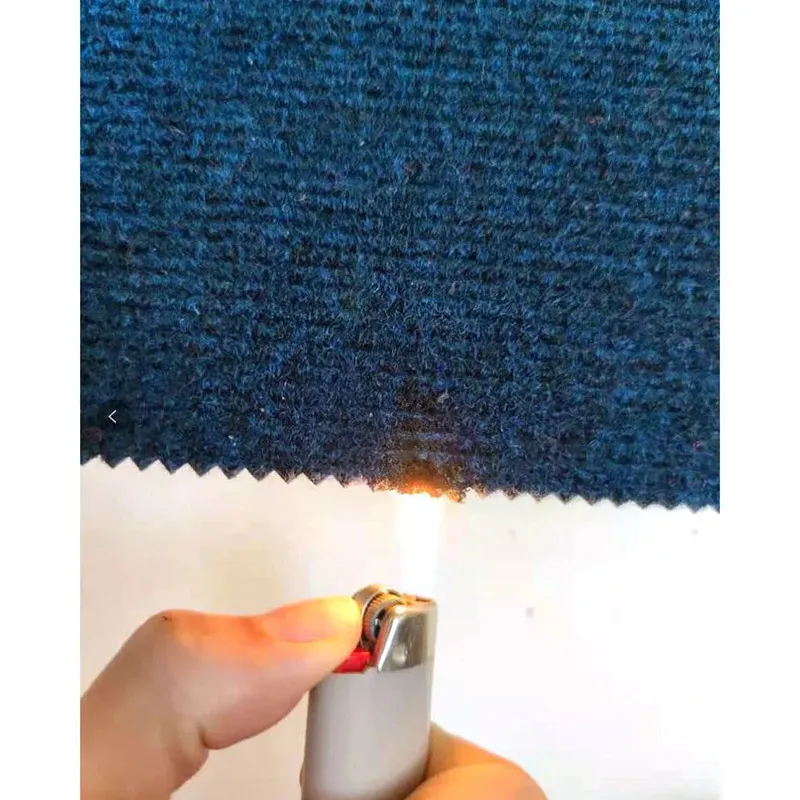

The non-combustible nature of fiberglass further enhances building safety. In situations of elevated temperature, fiberglass maintains its dimensional stability and does not produce toxic smoke, which is crucial for public buildings with strict fire-safety requirements.

How Does a Fiberglass Ceiling Enhance Indoor Comfort?

Fiberglass ceilings enhance comfort through:

-

Sound absorption that reduces reverberation

-

Light diffusion that creates a visually balanced space

-

Thermal insulation that supports energy management

-

Moisture stability that prevents warping and sagging

These benefits align with modern expectations for energy-efficient, human-centric building design.

Why Choose Fiberglass Ceiling Over Other Ceiling Materials?

The demand for fiberglass ceilings continues to grow due to their measurable advantages. This section explores why professionals increasingly select this material over gypsum board, mineral wool tiles, PVC panels, or metal ceilings.

Acoustic Performance: What Makes It Superior?

Compared with gypsum or metal ceilings that reflect sound, fiberglass ceilings absorb noise effectively. NRC values of up to 1.00 allow designers to achieve precise acoustic goals in:

-

Conference rooms

-

Classrooms

-

Theaters and auditoriums

-

Hotels

-

Open-plan offices

Effective sound control enhances productivity, reduces stress, and improves occupant satisfaction.

Why Is Fiberglass Considered a Safe Material?

Fiberglass is inherently non-combustible. It does not melt, drip, or ignite easily, maintaining stable physical properties even at high temperatures. This attribute makes it suitable for:

-

High-traffic public buildings

-

Transport terminals

-

Healthcare facilities where safety standards are strict

Compared with synthetic ceiling materials, fiberglass provides trustworthy fire-protection benefits.

Aesthetic Flexibility: How Does It Transform Interior Design?

Fiberglass ceiling panels come in a variety of:

-

Surface textures

-

Edge profiles

-

Colors

-

Shapes

Designers can choose between seamless monolithic looks, traditional square-grid aesthetics, or customized geometric shapes. The material supports modern trends such as minimalist ceilings, soft-tone acoustics, and suspended design elements.

Durability and Maintenance Efficiency

Fiberglass ceilings resist moisture, mold, and sagging, making them ideal for humid environments. Their lightweight composition also reduces load on ceiling structures and speeds up installation. Maintenance requirements remain minimal: simple dusting and occasional cleaning maintain long-term performance.

These qualities reduce facility management costs and extend product lifespan.

How Do Fiberglass Ceilings Function in Practical Applications?

This section addresses how fiberglass ceilings deliver operational performance within different building environments and how installation, acoustic control, and environmental impact play important roles.

How Does Installation Work?

Fiberglass ceiling panels are compatible with standard suspension systems:

-

Exposed T-grid systems for easy access

-

Concealed systems for a seamless aesthetic

-

Customized suspension frameworks for design-specific applications

Their lightweight nature minimizes installation effort and time. Contractors benefit from reduced labor demands and faster project turnover.

How Do They Deliver Acoustic Results in Real Environments?

In practical settings, fiberglass ceilings:

-

Reduce echo in large open rooms

-

Improve sound clarity for lectures and announcements

-

Control noise between adjacent rooms

-

Enhance privacy in offices or medical spaces

The ability to tune acoustics by combining ceiling panels with wall absorbers provides design flexibility without compromising aesthetics.

How Do They Support Energy Efficiency?

The thermal properties of fiberglass assist with:

-

Reducing heat transfer

-

Maintaining stable indoor temperatures

-

Lowering HVAC load

By optimizing insulation, fiberglass ceilings contribute to long-term energy savings and reduce carbon footprint in commercial operations.

Environmental Benefits

As sustainability becomes a priority, fiberglass ceilings fit into green building strategies due to:

-

Recyclable material composition

-

Long-lasting durability

-

Low maintenance needs

-

Compatibility with energy-efficient designs

These features support environmental certifications and long-term building performance.

What Are the Future Trends of Fiberglass Ceilings and Why Do They Matter?

The construction industry continues to evolve with technological advancement and sustainability goals. Fiberglass ceiling manufacturers innovate to meet global demand and enhance functionality.

Sustainable Material Innovation

Future fiberglass ceilings are expected to incorporate:

-

Higher recycled content

-

Bio-based binders

-

Low-emission coatings

These improvements help reduce environmental impact and support green building standards.

Smart Acoustic Systems

Advanced acoustic engineering will introduce:

-

Adaptive sound-absorbing panels

-

Integrated acoustic sensors

-

Ceilings that optimize noise levels automatically

As workplaces and entertainment venues adopt smart technologies, these systems will play a significant role in interior design.

Lightweight Structural Engineering

Manufacturers are developing even lighter yet stronger fiberglass cores. This will allow:

-

Greater architectural freedom

-

Faster installation

-

Lower maintenance cycles

Lightweight designs also reduce transportation emissions.

Customization and Aesthetic Direction

Future trends include:

-

Custom colors

-

3D surface textures

-

Organic shapes

-

Integrated lighting options

Fiberglass ceilings will evolve from functional building materials into major architectural features.

Frequently Asked Questions

Q1: How long does a fiberglass ceiling typically last?

A: A high-quality fiberglass ceiling can last 20–30 years or longer. Its durability comes from non-corrosive glass fibers and moisture-resistant surface treatments. Unlike mineral panels or metal ceilings that may deform or rust, fiberglass maintains dimensional stability over time. Regular light cleaning is enough to preserve its acoustic and visual performance.

Q2: Can fiberglass ceilings be used in high-humidity environments?

A: Yes. Fiberglass ceilings are designed for moisture resistance and do not warp or sag even in humid areas such as basements, kitchens, and certain commercial environments. Their structure resists mold and mildew growth, ensuring long-term hygiene and safety. However, proper ventilation should always be maintained to support overall building health.

Fiberglass ceiling stands out as a high-performance solution for modern construction due to its acoustic excellence, fire resistance, aesthetic versatility, and long-term durability. As building standards progress toward sustainability, comfort, and efficiency, the role of fiberglass ceilings will continue to expand. With technological advancements such as smart acoustic integration, lightweight engineering, and environmental innovation, the future of this product category remains promising.

For projects requiring reliable, high-quality fiberglass ceiling solutions, the craftsmanship and expertise associated with QDBOSS provide strong value. For more product information or professional consultation, contact us to discuss how fiberglass ceiling systems can support your next architectural or interior design project.