DIY Acoustic Panels

Send Inquiry

PDF DownLoad

Buy Customized DIY Acoustic Panels Quotation

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for OEM Manufacturer China DIY Acoustic Panels, We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

OEM Manufacturer China Acoustic Panel, Sound Proof, Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to offer you the best service. You should contact us if you will need more information. Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation.

1. Product Introduction of DIY acoustic panels

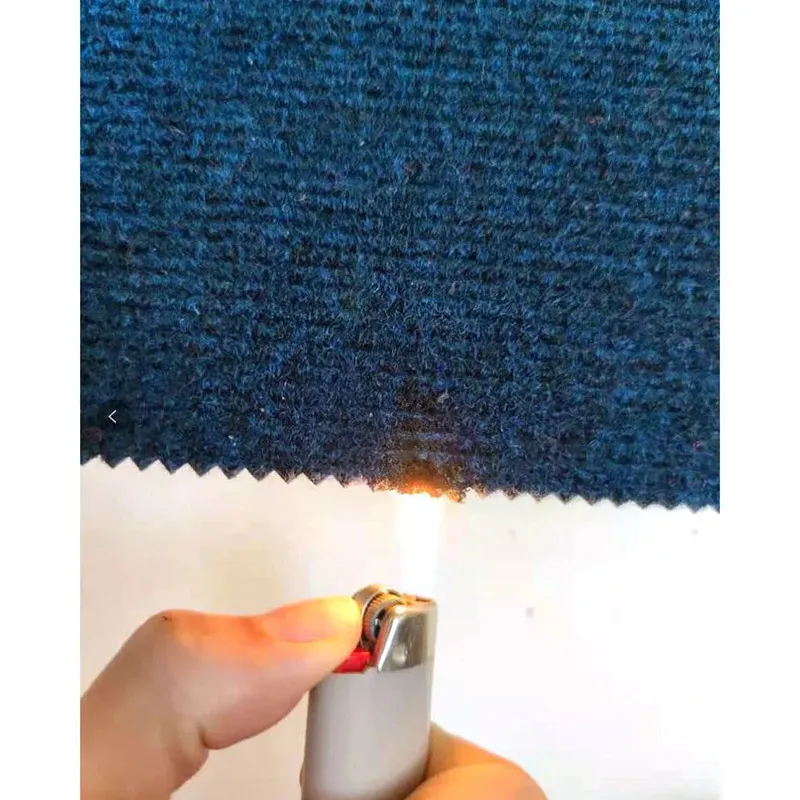

DIY acoustic panels is getting popular recently. People like to make the acoustic treatment by themselves. And polyester fiber panel is a good material for DIY. Polyester fiber panel is also called polyester fiber decorative sound-absorbing panel, which is a kind of decorative material with sound-absorbing function made of polyester fiber as raw material by hot pressing and needle punching. The product has the characteristics of decoration, heat preservation, flame retardant, environmental protection, light weight, easy processing, stability, impact resistance and easy maintenance. Become the preferred sound-absorbing material for interior decoration.

2. Specification of DIY acoustic panels

|

Core |

Polyester Fiber |

|

Thickness |

9mm 12mm |

|

Size |

1220x2420mm |

|

Weight |

1.2-2kg/sqm |

|

NRC |

0.9-0.95 |

|

Feature |

Flame retardant and Acoustic |

3 .Features of DIY acoustic panels

Decorative: the panel can be cut to different size and shape by CNC Cutting Machine

Flame-retardant: ASTM E84 Testing Class A Grade

Sound absorption: NRC0.7-0.95 with different air gap

Impact resistance, easy to clear, durable, thermal insulation, recycled material and Eco- friendly. It is an ideal replacement for the traditional fiberglass acoustic panel

4. Qualification of DIY acoustic panels

We have 7 modern workshops and production line, with patent technology to make the stable products. Qdboss produces flame retardant DIY acoustic panels, fabric wrapped fiberglass acoustic panel, fiberglass acoustic ceiling.

5. Delivery and Shipping Service of DIY acoustic panels

Qdboss DIY acoustic panels is packed in durable cartons, it is safe to be shipped by truck, sea and plane. Qdboss factory is located in the Jiaozhou, Qingdao, only one hour drive to the famous Qingdao Port and Qingdao Jiaodong International Airport. It can save the domestic shipping cost and provide fast and convenient delivery

6. Further processing of the DIY acoustic panels

The finished panel is 2420*1220mm, rectangle shape. We have the blade cutting station and laser cutting machine. And the panel can be cut to different sizes such as 1200x1200, 1200x600, 600x600, 300x300, or in round, hexagon shape, or any irregular shapes.

The four edges can be beveled, the connecting parts looks more natural on the wall in this way.

The white color can also be printed with patterns or pictures, to make it more decorative.

7 How to Install DIY acoustic panels

1 1. Before construction, you need to pay attention to the problem of board selection and layout, and you need to pay special attention to the slight color difference. On the side of the paste, find the center and draw the cross line, and the way of scheduling is Similar to the way of laying bricks. However, it should be noted that during the entire process, you need to wear gloves for construction to avoid pollution.

2. When cutting the board, a steel ruler and a utility knife are usually used to better cut and modify the board. If it is necessary to reduce the seam, the blade needs to be inclined by 0.5~1mm, which can effectively reduce the gap.

3. When pasting, you can use white latex or non-intrinsic all-purpose glue, so that it can stick to the cement or wood base more effectively, and it will take longer to use